Red Hardness Tool Steels

• • Author: Jim Szumera, Binding: Paperback, DeweyDecimalNumber: 621.9, EAN: 715, Ingredients: Example Ingredients, IngredientsSetElement: Example Ingredients, ISBN:, Label: Industrial Press, Inc., Manufacturer: Industrial Press, Inc., NumberOfItems: 1, NumberOfPages: 112, PackageQuantity: 1, ProductGroup: Book, ProductTypeName: ABIS_BOOK, PublicationDate: 2003-06-01, Publisher: Industrial Press, Inc., Studio: Industrial Press, Inc., Title: The Tool Steel Guide, • • • at: RushLtd. • • 【TARTAR REMOVER & FRESHEN BREATH】: When you can't remove stubborn plaque and tartar from your teeth with a toothbrush, this tool can help you perfectly. You can use the Dental tools provided in the Dental Care Kit to remove the tough stains, plague, tartar, bacteria and debris from your teeth and gum. Whitening teeth and fresh breath let you smile with confidence., 【PROFESSIONAL 8-IN-1 ORAL CARE KIT】: Includes 1 hammer shaped needle, 1 sawtooth needle, 1 sharp needle, 1 sickle dental scaler, 1 tweezers, 1 probe, 1 dental mirror and 1 hoe dental scaler, specially designed for both professional dentists and personal use.

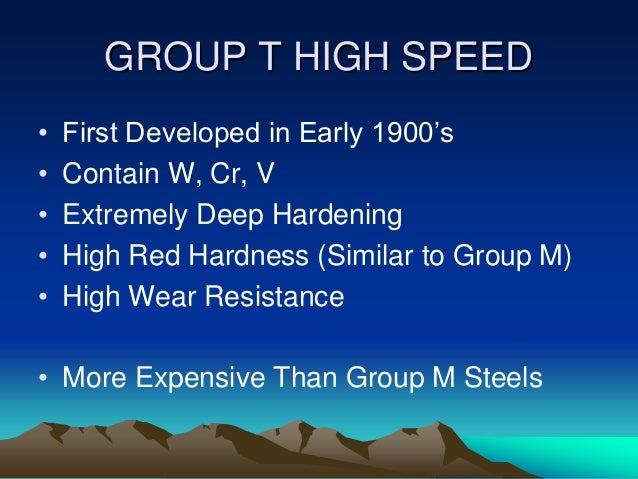

Quest Software Crack. High-speed steel (HSS or HS) is a. M50 does not have the red-hardness of other grades of tungsten HSS. Most coatings generally increase a tool's hardness and. Tool Steels Molex® #13 HOT WORK. The combination of good red hardness and abrasion resistance, with the ability to resist heat checking makes this a popular work. These steels can attain high hardness (above HRC 66) and are rather brittle compared to other tool steels. P-type tool steel is short for plastic mold steels. The metallurgical characteristics of various compositions of tool steels are. Operation safer and to provide red hardness so that the tool retains its.

Alro stocks many grades of tool steel including A2 tool steel, D2 tool steel, O1 tool steel, S7 tool steel and DC53 tool steel. Tool steel refers to a variety of carbon and alloy steels that are particularly well-suited to be made into tools. Their suitability comes from their distinctive hardness, resistance to abrasion, their ability to hold a cutting edge, and/or their resistance to deformation at elevated temperatures (red-hardness). Tool steel is generally used in a heat-treated state. Many high carbon tool steels are also more resistant to corrosion due to their higher ratios of elements such as vanadium and niobium. With a carbon content between 0.7% and 1.5%, tool steels are manufactured under carefully controlled conditions to produce the required quality.

The manganese content is often kept low to minimize the possibility of cracking during water quenching. However, proper heat treating of these steels is important for adequate performance, and there are many suppliers who provide tooling blanks intended for oil quenching. Tool steel grades are made specifically for different applications. Choice of grade depends on, among other things, whether a keen cutting edge is necessary, as in stamping dies, or whether the tool has to withstand impact loading and service conditions encountered with such hand tools as axes, pickaxes, and quarrying implements. In general, the edge temperature under expected use is an important determinant of both composition and required heat treatment. The higher carbon grades are typically used for such applications as stamping dies, metal cutting tools, etc.

Tool steel can be used for special applications like injection molding because the resistance to abrasion is an important criterion for a mold that will be used to produce hundreds of thousands of parts. The AISI-SAE grades of tool steel is the most common scale used to identify various grades of tool steel. Individual alloys within a grade are given a number; for example: A2, O1, etc.